SERVICES

Serve as an Expert Witness on Thermal Insulation related litigation

There are numerous law suits related to mold growth and construction defects in the building industry. Mr. Hart has experience in providing expert witness testimony as to construction defects in a particular building and its neglect following intrusion of water. Or, in other cases, there may be a construction defect but not the one identified by the plaintiffs as the cause.

Prevention of Corrosion Under Insulation

Corrosion Under Insulation (CUI) can be extremely costly for facility owners. While the root causes of CUI are well known and documented (i.e., water, oxygen, certain temperature range, and time, and it will be accelerated with the presence of corrosive chemicals), on a large industrial facility, CUI can be very challenging to minimize. After first inspecting a facility, Mr. Hart has developed facility specific programs to minimize CUI and thereby has improved safety while reducing operations and maintenance costs. Money spent on minimizing CUI is money well spent.

Perform insulation surveys

Mr. Hart has conducted extensive research and surveys. One type of survey is heat loss. Click on the link below to see the "Silent Bandit" video where his research is mentioned as a primary factor in discovering where and why heat loss occurs.

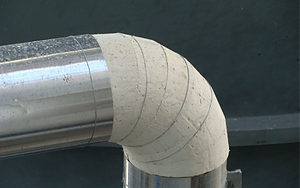

Inspections and surveys of thermal insulations materials and systems

Thermal insulation systems, correctly installed and maintained, can reduce thermal energy use at industrial facilities

by as much as 33%. Insulation is often overlooked since the lack of it may not prevent the success of an industrial process but may result in enormous amounts of energy waste. ARTEK Engineering can perform an insuation survey to determine where additional insulation is cost effective and how cost effective it can be. With this information, facility management will have the tools to make decisions on where to spend precious Operations & Maintenance funds.

Thermal efficiency evaluation of industrial processes and equipment

To determine thermal efficiency, ARTEK Engineering can provide analyses for industrial processes, power plant components, HVAC systems, and other applications involving the flow of liquids or gasses and the simultaneous flow of heat. Examples might be heat exchange in a manufacturing process, heat loss from insulated piping and equipment at a power plant, and thermal efficiency of an HVAC system component.

Write specifications for mechanical equipment

ARTEK Engineering can work with an owner/operator to help write specifications for mechanical equipment and other engineered systems that are to be custom designed and then put it to bid to vendors. For example, the owner or a manufacturing facility may need to order a new dryer. ARTEK Engineering can write the specifications and provide general drawings giving dimensions and materials or vendors to bid to. By taking this step, the owner is assured that they get the equipment that is needed for this industrial process.

Writing patent Invention Disclosures for mechanical equipment and processes

ARTEK Engineering has experience preparing Invention Disclosures as a first step towards filing a patent application

for mechancial equipment and processes. Furthermore,

ARTEK Engineering can provide technical illustrations to supplement the Invention Disclosure.

New Product and Services Development

Mr. Hart has successfully assisted clients with the development of new products and services. These have typically been new insulation products that either improve thermal or moisture performance, reduce craft labor to install, and / or reduce total installed cost. This new product and services development can assist both manufacturers and insulation contractors.

Infa-Red (IR) inspections of thermal insulation systems

When a large thermal insulation job is completed, it is very difficult to determine the quality of the installation job. However, once the equipment is brought into operation, the effectiveness of the thermal insulation system can be evaluated with a thorough Infra-Red inspection. ARTEK Engineering can provide an engineer to work with a local IR technician to make certain the IR equipment is properly adjusted for the temperatures involved, that the technician takes representative IR photos, and that he interprets the IR photos correctly.

Increasingly, thermal insulation contractors are being required to demonstrate the adequacy of their work through an IR inspection following completion of the job. By hiring ARTEK Engineering to represent the contractor, the contractor is assured that the quality of the job is adquately represented. Otherwise, IR photos could be shown to suggest a poor quality job due to the technician's improper adjustment of the equipment or misinterpretation of the photos.

For owners/operators of industrial equipment, IR inspections can be used to locate degraded or wet thermal insulation or areas that were never properly insulated in the first place. By spending the money up front, soon after the contractor's job. Likewise, by spending the money periodically, the owner/operator can check wheather leaks have resulted over time, allowing water intrusion into the insulation or whether insulation has degraded from vibration,high temperature excursions, or other sources of damage.